Our specialists will be pleased to assist you with any of your cryogenic needs.

Eidgenössisch Technische Hochschule ETH, Zurich, Switzerland

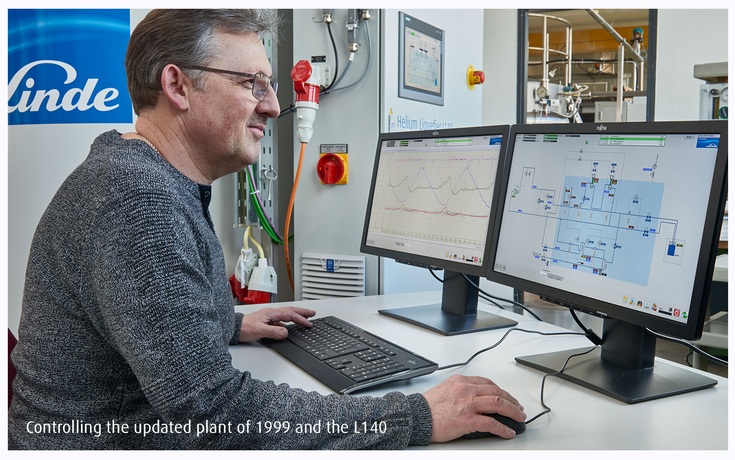

Modernization of the Cryogenic Infrastructure

For more than two decades, ETH Zurich has relied on helium liquefaction systems to support its cutting-edge research. However, after 22 and 19 years of operation, the two existing liquefiers — installed in 1996 and 1999 — were showing their age.

At the same time, the university anticipated a steady increase in helium consumption over the coming years. This combination of aging equipment and rising demand posed a critical question: How can ETH Zurich secure a reliable, efficient helium infrastructure for the future?

Replacement or upgrade?

The older system from 1996 had reached the end of its lifecycle. Upgrading it would not deliver sufficient performance gains, making replacement the only viable option.

The 1999 system, however, still had many components with available spare parts. Could it be modernized to meet current standards and extend its operational life?

ETH Zurich turned to Linde Kryotechnik for expert guidance. With decades of experience in cryogenic technology and modernization projects, Linde Kryotechnik proposed a hybrid solution:

- Replace the 1996 liquefier with a new, high-efficiency L140 unit from Linde’s standard program (see comparison above).

- Upgrade the 1999 plant with state-of-the-art control systems, electronics, and critical components to ensure reliability and compliance with modern safety standards.

The Modernization Process

In 2017, ETH Zurich implemented this plan. The modernization of the 1999 system included:

- Installation of a new control system and concept, enabling fully automated operation.

- Replacement of all electronic components, control valves, and pressure and temperature sensors.

- Integration of advanced safety measures following a comprehensive HASOP safety study.

These upgrades transformed the 19-year-old plant into a system that operates like new—while maintaining compatibility with the latest technology and ensuring spare parts availability for years to come.

The Modernization Process

In 2017, ETH Zurich implemented this plan. The modernization of the 1999 system included:

- Installation of a new control system and concept, enabling fully automated operation.

- Replacement of all electronic components, control valves, and pressure and temperature sensors.

- Integration of advanced safety measures following a comprehensive HASOP safety study.

These upgrades transformed the 19-year-old plant into a system that operates like new—while maintaining compatibility with the latest technology and ensuring spare parts availability for years to come.

The Outcome: Efficiency and Reliability

Today, ETH Zurich operates a dual system:

- A brand-new L140 liquefier delivering increased performance and energy efficiency and makes the major contribution to the necessary increase in performance.

- A modernized 1999 plant that continues to function reliably under a unified control platform.

This strategic approach achieved several key benefits:

- Cost Optimization: Avoided the expense of two new plants by modernizing one existing system.

- Energy Savings: Improved efficiency at different operating points, reducing energy consumption.

- Future Readiness: Ensured long-term reliability and compliance with current safety standards.

By combining replacement and modernization, ETH Zurich secured a robust helium infrastructure that meets growing demand while minimizing investment costs—a true success story.